Global warming and environmental changes have increased public interest in air quality over the past few years. As the significance of the outdoor environment grows, people are also becoming aware of the impact healthy indoor air quality can have on their family, friends and colleagues both at work and at home. With this mounting interest in mind, Airthings has decided to delve deeper into the different indoor air sensors on the market. We shall thoroughly break down the components to our sensors, and explain why they are most effective. Helping you to make an informed choice.

We shall start with Carbon dioxide sensors. Carbon dioxide is commonly known as CO2, a greenhouse gas which is harmful in high doses. Years of research has gone into the effects of carbon dioxide on the planet. As the UK’s National Meteorological Office (Met office) warns, “Since the Industrial Revolution, atmospheric CO2 has increased by over 40% to levels that are unprecedented in at least 800,000 years”. Not only is it bad for the environment, but when this ever-increasing rise of CO2

collects indoors, there can be negative consequences on the population’s health.

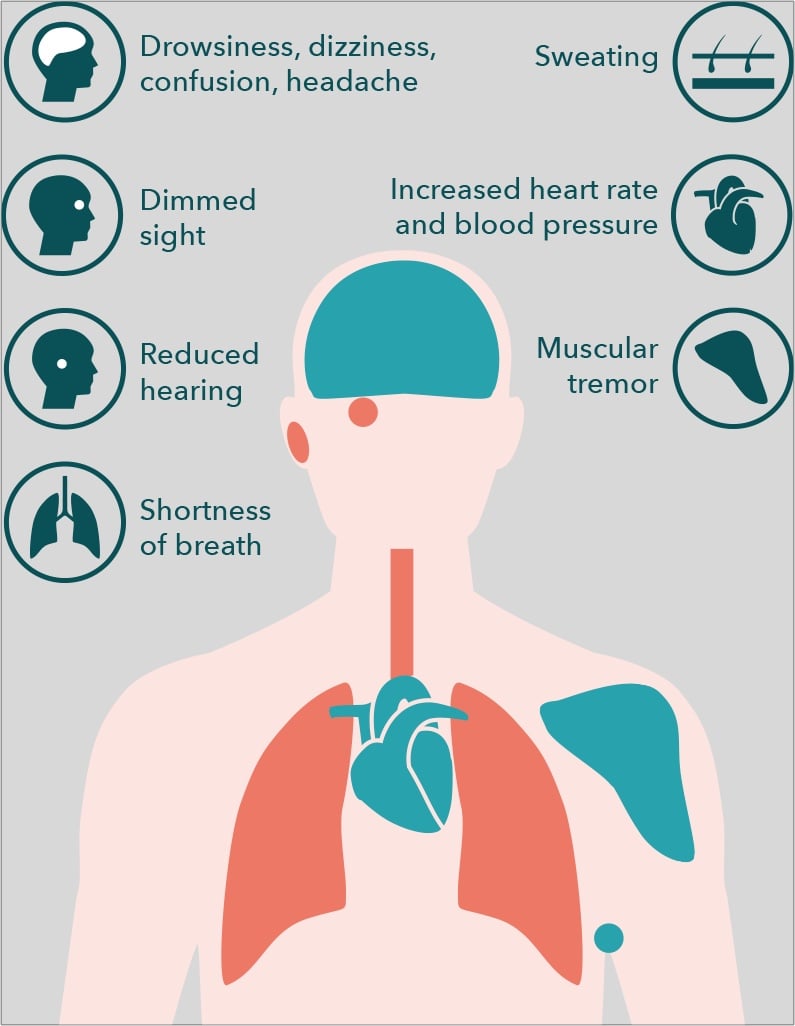

The effects of excess CO2:

This ever-increasing rise is creating a drive for high-quality carbon dioxide sensors in the home and workplace.

Two options, two different results.

There are many types of CO2 sensors on the market. The two most common types are NDIR and a method that works from a calculation.

NDIR sensor

Airthings devices use NDIR sensors. They continuously measure the amount of CO2 gas molecules present in the air.

NDIR technology:

There is a compact NDIR sensor installed in every Airthings Wave Plus device.

It measures the amount of CO2 gas molecules in the chamber, which samples air from the room it is placed in. A light shines on a sensor at the other end of the chamber. As the light passes through the chamber, only CO2 is absorbed. The sensor then measures how much light has passed through the chamber, excluding the CO2 molecules. This gives an extremely accurate result of exactly how much CO2 is present in the air. It actively counts the molecules every five minutes to ensure the most up to date statistics are provided.

VOC sensor:

Alternatively, many volatile organic compound (VOC) sensors are often used to measure CO2. Through a complex formula, the results are calculated based on the presence of VOC’s in the air. This option is often preferred if a device does not have space or means to install a sensor that is specifically designed to measure CO2.

Chemical carbon dioxide sensors:

Chemical carbon dioxide sensors offer the benefit of low energy consumption and small size. However, according to research, their overall lifetime is much shorter in comparison to NDIR sensors. NASA’s Glenn Research Center has been working on a solution to this problem and has recently launched a new type of carbon dioxide sensor which improves their pre-existing chemical sensor technology.

NDIR vs VOC in action:

Let us now use genuine readings from Airthings HQ to demonstrate some potential issues with using a VOC sensor to perform a calculation.

VOC sensors often do not control for all extraneous variables such as ventilation systems or room population.

The graph above shows the VOC and CO2 levels at Airthings HQ. On November 3rd, the CO2 levels decrease. This is a weekend, so even though the ventilation system is off, the CO2 levels decrease because there is no one in the office expelling CO2through breathing.

If we were to draw co2 levels solely from the VOC readings, we would receive inaccurate results. Although the CO2 levels decrease on November 3rd, the VOC levels actually rise. VOC’s are being emitted through the off-gassing process from products such as carpets and furniture. Usually, the ventilation system counteracts this rise, however, due to the weekend, the system was switched off.

On November 3rd, VOC and CO2 levels acted very differently at Airthings HQ. Therefore if we were to calculate CO2 levels based on VOC, the results would be incorrect.

Airthings Wave Plus CO2 Sensor specifications:

- NDIR Sensor (Non-Dispersive Infra-Red)

- Measurement range 400–5000 ppm

- Non condensing 0 – 85%RH

- Optimum Accuracy ±30ppm ±3% within 15 – 35°C or 59 – 95 degrees fahrenheit and 0 – 80%RH can be reached after multiple settling cycles on locations with natural indoor CO2 fluctuations

Subscribe to our newsletter below for the latest indoor air quality news and exclusive offers!

.webp)

%20(1).webp)

%20(1).webp)